Get your facts first, then you can distort them as you please.

Mark Twain

The Great Debate

There has been much conversation and debate about the differences between, not only the different woods in bagpipes, but bagpipes constructed of plastic. Plastic is not the correct term, per se, but I will use it to describe the alternative bagpipe materials that are generally viewed as plastics. Which material is best for sound? The issues surrounding the different wood and ‘plastic’ bagpipes are generally related to weight, appearance, sound, and condensation of moisture. I present here a discussion of the facts with a healthy dose of science.

Alternative Materials: ‘Plastic’ Bagpipes

‘Plastic’ bagpipes have been or are being made of PVC, Delrin, and Acetyl. Most plastic pipes are now made of Delrin, a highly crystaline polymer, and this is a popular alternative to wood bagpipes. Delrin® is also known as Polypenco® and is, as I understand it, an acetyl homopolymer. A competing material used by R.G. Hardie for their Hardie and Peter Henderson ‘plastic’ pipes and McCallum bagpipes is Acetyl”. Acetyl® or Black Acetyl, as I understand it, is an acetyl copolymer and is not a strong or hard as Delrin. It is apparently easier to finish than Delrin® and may be why Hardie and McCallum uses it for their ‘plastic’ pipes (source). Plastic Hardie and McCallum chanters are made of Delrin®, though. Noteworthy, is that there are also pipes made from Polypenco® with cellulose polymer bore inserts, carbon fibre, and aluminum.

History of ‘Plastic’ Bagpipes

There is some controversy over who first used acetal for bagpipes but in all likelihood it was Jack Dunbar of Dunbar Bagpipes in St. Catherines Ontario. Jack apprenticed under Peter Henderson Bagpipes in the 1930s and 40s and was a partner in a bagpiping company, Piob Mhor, 1948-1951. After emigrating to Canada he began doing bagpipe repairs in his garage, which morphed into Dunbar Bagpipes. African blackwood orders were slow to arrive in the 1970s and Jack experimented with impregnated maple (as did Sinclair bagpipes) and extruded thermoplastics. Delrin® soon came out as the superior material and Dunbar continues to manufacture bagpipes with this material. Norm Kyle of Bagpipes & Regalia in Edmonton Alberta made extruded PVC and acetal pipes in black and clear in the 1980s and there is a suggestion that at least one Scottish maker was experimenting with thermoplastics during the same period. In 2016 McLellan Bagpipes introduced their Revelation Line of bagpipes, which are Delrin® will cellulose polymer bore inserts to absorb moisture. For more details on these materials and the evolution of alternative material bagpipes, please see my Plastic and Other Bagpipes? section.

I will focus specifically on what could very well be the superior plastic material, Delrin® or Polypenco®, from this point forward. This material is dimensionally stable and durable to the extent that that the best warranties in the industry are for bagpipes made with this material. For example, Dunbar warrants their poly pipes for life (McCallum warrants Acetyl® for 10 years); does Polypenco® – Acetyl® sound like a substandard material? Despite this, poly bagpipes continue to be maligned and misunderstood, often by individuals who have never played a set let alone seen or even heard one. Let’s examine a few factors including weight, sound, and moisture considerations…

When you can measure what you are speaking about and

express it in numbers, you know something about it; but when

you cannot measure it, when you cannot express it in numbers,

your knowledge is of the meager and unsatisfactory kind.

Lord Kelvin

2011 Dunbar P2C tenor drone shoulder. The Polypenco® looks a little light-coloured with a flash but in reality is quite dark. See more photos below.

Here’s an example of Polypenco® duplicates of a teens to twenties ebony wood-mounted blowpipe and stock artfully produced by Dunbar Bagpipes:

Teens to 20s ebony Henderson wood-mounted blowpipe and stock beside Polypenco® duplicates. Rick Pettigrew at Dunbar bagpipes does a fantastic group reproducing parts.

Which is which?

Weight

Poly pipes are sometimes considered to be heavier than wood bagpipes. Let’s look at the numbers using the specific gravity ratio as converted to density (gm/cc). ‘Polypenco’® has a density of 1.42 gm/cc (source) to 1.49 gm/cc (source) depending on the source. This is heavier than than the dry weight densities of African blackwood (1.08), cocus wood (0.92), coccobolo (0.89), and ebony (0.82). Seasoned bagpipe wood has a moisture level of at least 6% and probably as 8% (source) so a comparison to the 12% moisture content stats for these woods would likely be a little closer to the actual weights: African blackwood (1.27), cocus wood (1.16), cocobolo (1.10), and ebony (0.96). Here’s that same table from above but with poly for a neater comparison:

Material Latin Name Dry Weight 12% Moisture Weight*

Polypenco®/Delrin® Plasticus plasticus (1.42) (1.42)

Delrin & Cellulose poly Plasticus polymerus Lighter than above!**

African blackwood Dalbergia melanoxylon (1.08) (1.27)

kingwood Dalbergia cearensis (0.98) (1.20)

katalox Swartzia (spp.) cubensis (0.94) (1.15)

cocus wood Brya ebenus (0.92) (1.16)

coccobolo Dalbergia retusa (0.89) (1.10)

mopane Colophospermum mopane (0.88) (1.08)

Burmese blackwood Dalbergia cultrata (0.83) (1.04)

ebony Diospyros crassiflora (0.82) (0.96)

laburnum Laburnum anagyroides (0.69) (0.85)

East Indian rosewood Dalbergia latifolia (0.70) (0.83)

* Not really available for polypenco so I’ve used dry weight here!

** MacLellan Bagpipes makes a Delrin bagpipe with cellulose polymer bore inserts which

would presumably lighten the density of the bagpipe.

Thus, the difference in density between ebony and blackwood is actually pretty much the same (or perhaps even greater) than the difference between poly and blackwood. There is likely much variability in the specific density of wood of the same species based on various factors, as well. This variability may well be part of equation explaining why some pipes appear to have different tonal qualities than others of the same material, from the same era, by the same manufacturer (bores being another part, all else being equal).

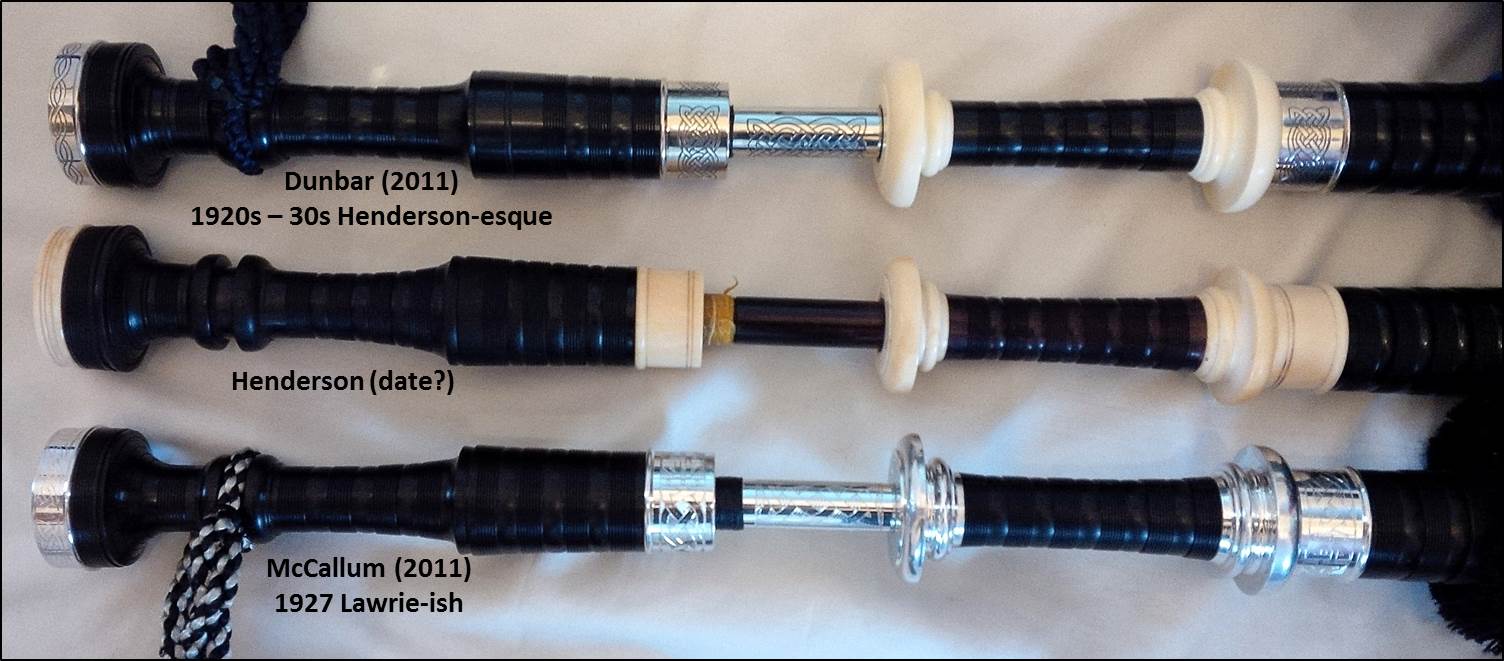

So yes, poly appears to be a little heavier than wood, but what does this perceived difference in weight mean? Not much. I have 2011 Polypenco® Dunbar P2Cs with engraved nickel slides, ferrules, and drone caps. This set weighs 6.5 lbs, almost identical to my 2016 blackwood, moose, and silver Colin Kyos. Both of these pipes are 0.2 lbs less than a set of 2011 McCallum engraved full alloy African blackwood pipes which weigh 6.7 lbs that I used to own. All sets were weighed without moisture control systems and are identically set up with reeds and chanter. All sets are tied into Bannatyne extended small bags except the McCallums had a hybrid bag, which is a little heavier and could account for some or all of the the difference in weight. That said, the Dunbar drone tops are thicker and long than those of the McCallums, the Dunbar nickel ferrules and slides are arguably heavier than the McCallum alloy versions and yet the Dunbars are lighter. All in all, these poly and blackwood pipes weigh pretty much the same. Here’s an image of the Dunbar’s and McCallum’s with my WWI Henderson’s (as as aside, my Hendersons only weigh about 5.6 lbs and are my lightest pipes):

Thus, the density differences do not appear to be that significant at least with the amount of material used to make bagpipes (maybe with pipes 2x or 3x the size differences would be more pronounced). I suspect that part thickness and other aspects of dimensionality, plus the type of materials used for mounts and ferrules, bag type, etc. make more of difference in overall weight of the bagpipes than the specific density of the main materials. These factors may also contribute to tonal differences, but that is a whole other discussion touched upon here.

MacLellan’s Revelation Bagpipes utilize Delrin® with cellulose polymer (think reed bodies like in Ezeedrones and Canning) and thus are likely lighter than comparative Delrin pipes in a similar profile. The tone is said to be more refined that straight Delrin.

To extend this comparison, one would have to have an identical set in both materials to make a perfect comparison.

Appearance

I have had experience comparing Dunbar Polypenco® and blackwood drones and McCallum blackwood and Acetyl® drones. While the different sets by both brands look very similar, to my eye, there is less difference between poly and blackwood in Dunbar than McCallum. Below are four images of a set of an acquaintance’s Acetyl® McCallums dressed up pretty much identical to mine with my blackwood McCallums. For the most part, both sets appear nearly identical. However, the closer you get the more differences in the base materials are revealed. In this case there are two: colour and combing. Acetyl® is a little grey looking comparing to blackwood (and also polypenco at least to my eye). Additionally, at least with McCallum, the number of combs on the tenor drone tops sound chamber are six compared to eight in on the blackwood pipes; this is not the case with Dunbar bagpipes. Why this be for McCallum is unknown to me. Perhaps with Acetyl® being a little softer than polypenco fewer combs were easier to turn without issue. Or, perhaps there is a design change at McCallum; my blackwood set is 2011 and the Acetyl® set is 2016. In any event, this is a minor quibble, as you can see that the McCallum Acetyl® set are quite beautiful.

Additionally, I play a set of Dunbar Polypenco® pipes and, respectfully, believe that the combing and beading is closer to Dunbar African blackwood sets than what we see with McCallum sets. The combing on the McCallum Acetyl® pipes has fewer teeth than on wood sets. Whether McCallum has changed their combing (comparison was between 2017 Acetyl® and 2011 blackwood) or fewer combs make manufacturing easier I don’t know. There is more information here. Here are some Dunbar Polypenco® and blackwood pipes for comparison; the beading and combing is nearly identical between the two sets:

Dunbar Polypenco and African blackwood pipes. The beading and combing is nearly identical in depth and number.

Of course, the proof is in the pudding. What about the sound? I have been playing my Dunbar Polypenco® for close to five years and the tone is outstanding. Due to inclement weather I recently played them in a church for a funeral and they had fantastic harmonics. I have been hearing the above McCallum Acetyl® set at band practices, with the band and solo tuning, and, guess what — they sound fantastic, too.

Now for further discussion on sound…

Sound

A common complaint is that poly bagpipes sound different from wood bagpipes. Most of this unjustified, with likely 99% of most people, many pipers included, not being able to tell the difference between poly and wood bagpipes being played. I have Dunbar P2C pipes and four sets of wood pipes. One is African blackwood, two are ebony, and the other is cocus wood; I know what each set sounds like on my shoulder and in recordings but I would be hard pressed to describe a particular characteristic that my poly pipes have over the other pipes. I wrote once on a forum that I thought I could detect a difference, perhaps a brassier tone from the polys but now I am not so certain. The bores could be smoother in poly pipes but would that change the tone? Or perhaps it is volume?

There is very likely a difference of some type based solely on the characteristics of the materials. This has been fairly well-documented by experienced pipers: ebony sounds different from cocus wood sounds different from African blackwood sounds different from ebony. One would have to compare the same bagpipe set-up with identical reeds, etc. type 1 wood to type 2 wood, poly to type 1 wood, poly to type 2 wood to fairly discern a difference in sound between the two materials. I know of one instance where an individual owned Dunbar Polypenco® and Dunbar blackwood pipes and found no difference in the tone of the bass drones though the poly tenors appeared to be a bit louder in volume. The latter point was explained elsewhere as resulting from a slightly larger bore diameter in the Polypenco® pipes.

MacLellan Bagpipes has come up with a very innovative way of addressing a perceived harsh tone (and perceived moisture issues) in plastic bagpipes with their Revelation line. These new bagpipes utilize 1) cellulose polymer inserts in all bores, and 2) removable drones with inserts to promote drying. For points 2, see below for images and more details. The addition of the lining is said to help mellow the tone of plastic bagpipes. I personally don’t find plastic bagpipes, at least the Dunbar and McCallum versions I’ve heard, harsh as suggested by some and I would put forth that most people, including pipers, would not be able to tell the difference in tone between wood and plastic. The tone may be different, but not necessarily harsher. I would rate the tone of my Polypenco® Dunbars, blackwood Colin Kyo and McCallums, and cocus wood Hendersons with Kinnaird Evolution reeds in all three as excellent. Certainly, the sound signature is different, but bores and reeds are just as important to tone as the bagpipe materials.

It is generally assumed that Polypenco® chanters are louder than their wooden counterparts. I have played chanters made of Polypenco®, laminated wood, and African blackwood and will admit that there may be differences in the timbre or volume of each chanter. Poly chanters may be a little louder but still sound like, guess what, chanters. The same could be said of bagpipes, each with their individual characteristic.

Moisture

Another complaint is that Polypenco® pipes condense more water than wood pipes, informally and formally (re the latter, see the above on McLellan Revelation bagpipes). Of course, it is not my intention in any fashion to minimize moisture issues, as it can be a huge issue in wood bagpipes,too. McLellan has developed a unique solution to moisture for their Revelation polypenco bagpipes that I suspect would be just as effective in wood bagpipes. But back to the issue at hand: is there more moisture condensing in plastic bagpipes over wood bagpipes? I believe this to be a big misconception and I have the data to prove it. First, more on the properties of Polypenco®.

Believe it or not, Polypenco®/Delrin® will absorb water: 0.22% in 24 hours with a maximum saturation of 0.70% (source). How does that compare with the different woods? That would depend on the type and state of the wood before water was introduced. Recall that seasoned blackwood for bagpipes would vary around 6 to 8% moisture. Has the wood been oiled? How long before last being played, etc.? I don’t have any hard numbers on how fast wood absorbs water but if the wood has been oiled with the proper oil would this material not be somewhat similar in hydrophobic properties as Polypenco®? Probably not exactly but oil would certainly slow the absorption of water (source) as well as being highly recommended by many.

The Test

I often use a Max-Dry moisture control system (MCS) when playing any of my pipes. This is basically a jar with three desiccant cartridges and some paper towel hooked up to the blowpipe stock with a hose. It traps quite a bit of moisture as I outlined here in a detailed test. However, how much water escapes to condense inside the bag, reeds, and bores of your pipe? I set out to find the answer, not only for pipes in general, but to see if there are differences between poly pipes and wood pipes.

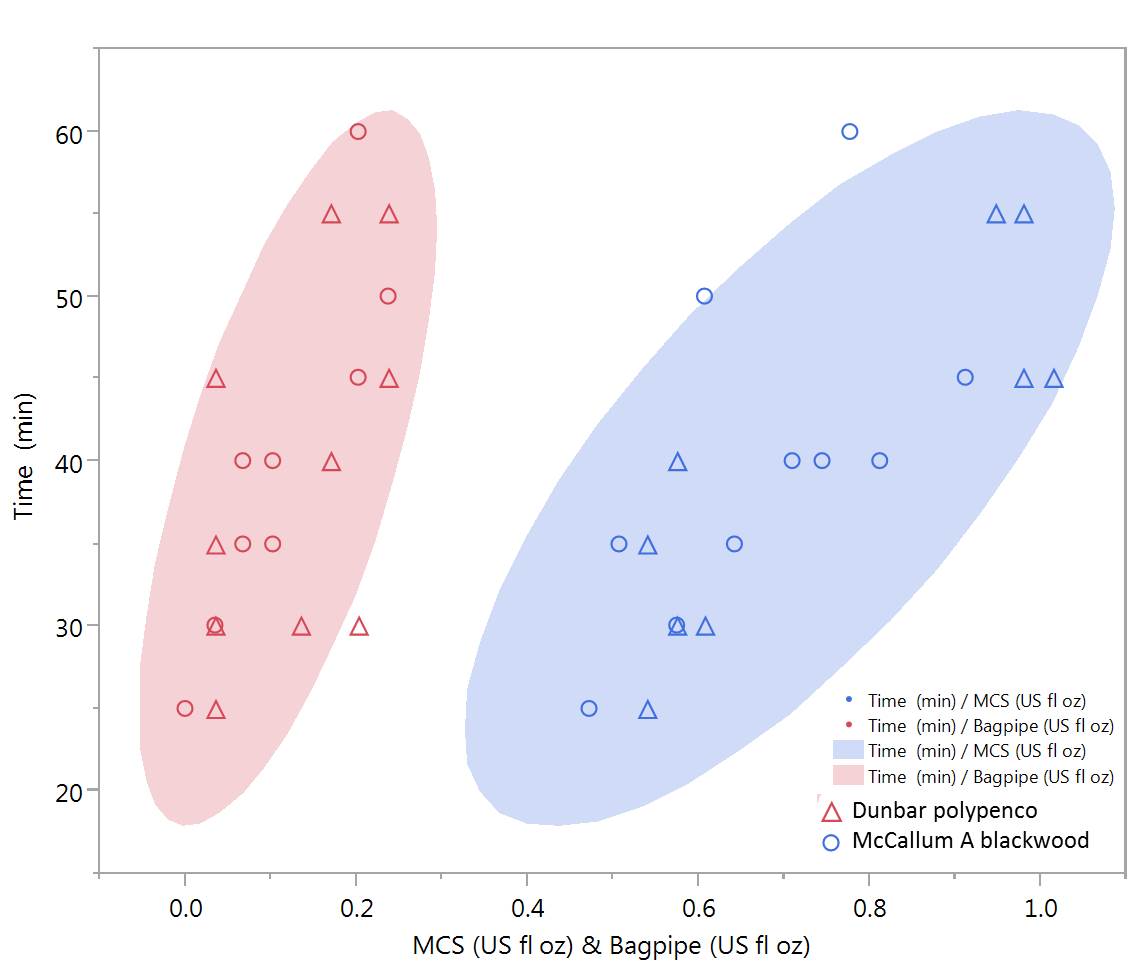

Using my Polypenco® Dunbars and blackwood McCallums I played each set 10 times and measured and recorded the amount of water in the MCS and the pipes. This was accomplished by weighing all of the components in grams before and after playing and calculating the difference in weight. The weights were then converted to US fluid ounces using a factor of 0.0338140225589 ounces per gram. The time I played varied from 25 minutes to 60 minutes and the temperature ranged from ~18 ºC – 20 ºC (64 ºF – 68 ºF).

After the data was collected I conducted some normality tests, tests of means, and some regressions to determine if there are differences in the amount of moisture in poly pipes compared with African blackwood pipes.

Results

The results are very conclusive; there is absolutely no difference in the amount of water condensing the the bag, reeds, or bores of poly pipes vs. wood (African blackwood) pipes.

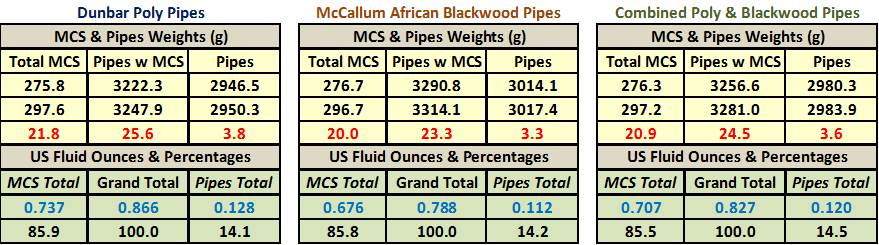

Here are some summary statistics for poly, blackwood, and combined pipes by moisture control system and the bagpipes themselves. The distribution of moisture for the moisture control system and the bagpipes are close to exact for both sets of pipes. The MCS collects a mean of 86% of the water with 14% collecting in the bagpipes. There appears to be slightly more moisture overall in the poly pipes compared to the blackwood pipes: 0.87 fluid ounces compared to 0.78 fluid ounces. But is the difference significant, at least from a statistical point of view? No.

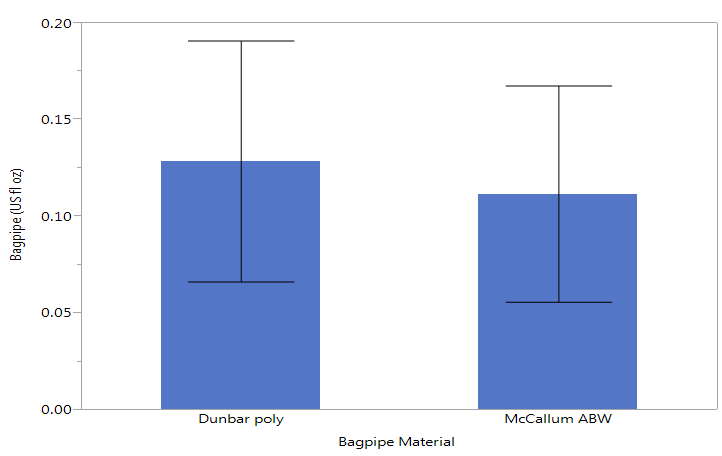

Here is a distribution of the values for total fluid between the bagpipes with 95% confidence intervals. The large overlap of the 95% confidence intervals, along with a test of means, indicate that there is no difference in the amount of moisture between the two bagpipes. Not even close.

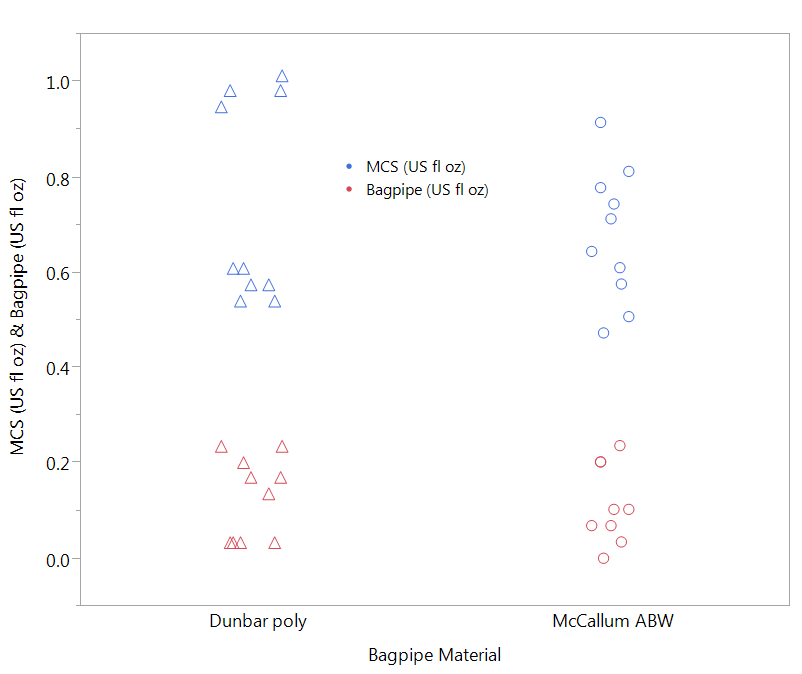

Here is how the distribution of data looks broken down into moisture control system and bagpipe by bagpipe material. One can see that there is really no difference in the amount of moisture condensing in the pipes. However, the moisture control system seems to retain a little bit more water in the poly pipes. This is what drives the mean up for the poly pipes. However, the difference is not significant as evidenced by a non-parametric test of differences.

Moisture Over Time

Here’s what the data look like with MCS (blue) vs Bagpipe (pink) over time. The triangles are the poly pipes and the circles are the blackwood pipes. The relationships between the moisture captured and time played are quite linear for the bagpipes and the moisture control system. However, note how the moisture control system captures more water over time than the pipes themselves. This is a good thing. Of course there is no difference between the poly and blackwood pipes.

Note the triangles are Dunbar polypenco pipes and the circles are McCallum African blackwood pipes, irrespective of colour. Pink/red is moisture in the pipes and blue is moisture in the moisture control system.

Caveats

These tests were only conducted at one location (relatively dry at ~30-40% humidity) and around 20 ºC (70 ºF). The amount of moisture condensing would likely increase at lower temperatures and decrease at higher temperatures. One would have to compare wood and plastic pipes at either ends of the spectrum to capture the full range of conditions. That said, as demonstrated above, I don’t suspect that there would be significant differences.

New Developments

Although I’ve demonstrated that there is no real difference in moisture buildup between plastic and wood pipes, as noted above, the belief that moisture is an issue with plastic pipes is fairly widespread. MacLellan Bagpipes has come up with a very innovative way of addressing perceived moisture issues in plastic bagpipes with their Revelation line. These new bagpipes utilize 1) cellulose polymer inserts in all bores, and 2) removable drones with inserts to promote drying.

MacLellan Bagpipes Revelation line with cellulose polymer linings and removable stocks. Image from http://www.highland-pipemaker.com/Sustainable%20bagpipes/Delrin/Delrin%20pipes.html

While I am not convinced that moisture is more of an issue in plastic pipes compared to wood pipes, this innovation may be generally an effective means to addressing moisture in any set of pipes. One question I would have is whether the polymer cellulose will expand with moisture and it can do in drone reeds made of a similar material.

Additionally, the addition of the lining is said to help mellow the tone of plastic bagpipes. I personally don’t find plastic bagpipes, at least the Dunbar and McCallum versions I’ve heard, harsh as suggested by some and I would put forth that most people, including pipers, would not be able to tell the difference in tone between wood and plastic. The tone may be different, but not necessarily harsher. Drone reeds would likely have more of a tonal effect that would the drone material. I would rate the tone of my poly Dunbars, blackwood Colin Kyo and McCallums, and cocus wood Hendersons with Kinnaird Evolution reeds in all sets as excellent. Certainly, the sound signature is different, but bores and reeds are just as important to tone as the bagpipe materials.

OK, back to plastic bagpipes…

‘Plastic’ Pipes: The Facts

Despite this, poly bagpipes have gotten a bad rap, often by pipers who have never played a set let alone seen or even heard one. I am a newish piper who started with poly pipes and I would not hesitate in recommending a set of poly pipes for beginners and anyone else, for that matter. I have had my used set of Polypenco® Dunbar P2Cs since November 2013 and they have been pretty much the perfect instrument for various reasons:

1) Durability: As a beginner it is not uncommon to knock your pipes about on all manner of surfaces on a fairly regular basis. I have no fear of damaging anything, other than my pride and a little door trim, with poly pipes (an acquaintance with 30+ years experience has broken his bass drone twice in doorways — he’s a tall boy). I can also use the time to practice good pipe maintenance to minimize risk of cracked ABW pieces should I eventually purchase a set of ABW pipes (which I have three); five pipers with ABW I know have all had cracked stocks or blowpipes in the last couple years. Add myself with my McCallum ABW pipes and you have six. Why? Moisture. But more of that explanation here = Operator Error. Back to my poly pipes. Once, after the longest session playing to date, I left my pipes overnight intact and leaving against the wall as I normally do — the next day most joints above the stocks were completely seized due to moisture expanding the hemp! I can only imagine what might have happened if I had done this with a set of ABW — as a beginner I would not have trusted myself to pull them apart without damaging anything. I now take any set of bagpipes apart and swab everything after playing.

Additionally, I am unafraid to take my poly pipes anywhere under any conditions and I have no issue letting anyone handle them, including curious kids. I have some piper friends who will barely let me touch their pipes lest I damage them, run to move them out of the sun, and are constantly looking over their shoulder for their pipes. For me, particularly when I was a beginner beginner (I am still a beginner), having poly pipes = less stress for those times when I don’t want to risk playing my wood pipes. They are my go-to travel and outdoor cold-temperature pipes.

2) Price: I bought mine used with everything I need for $635 and there are even lower priced examples out there. This is a great price point from which to enter into this hobby for many individuals, particularly if you’re uncertain how far it will take you or how serious you will be about it. If it’s a total bust I will likely get all of my money back on my investment.

3) Time for Research and Saving Up $ for an African blackwood Set: If one becomes proficient enough and decides they want an ABW set they will have plenty of time with which to research and choose a set. I’ve been able to try out ABW Naills, Gibsons, McCallums, Hendersons, Colin Kyos, and Robertsons and have formed opinions of what bagpipes I like, blackwood or not (tone, style, bling, etc.).

I say poly pipes are ‘pretty much’ the perfect instrument only because they are not wood! Having a number of vintage and contemporary wood bagpipes and stringed instruments I really appreciate the feel and look of wood. What about moisture? Do poly pipes actually condense hold more water than ABW pipes? Not according to some rigorous tests I’ve just conducted — see here for the startling results!

4) Weight

Some have said that poly pipes are heavier than wood pipes: not so! A set of full alloy blackwood McCallum bagpipes I used to own weigh more than my poly and 3/4-nickel Dunbars. More on that here.

5) Tone

A short comment on tonal differences between poly and African blackwood from a relative beginner: there isn’t much difference. Perhaps it is just my poly Dunbars loaded with Croziers or Kinnairds but of those pipes I’ve heard/played (Naill with Kinnairds/Cannings, Naill with Ezees, Gibsons with Cannings, Robertsons with Kinnairds, ebony Hendersons with various reeds, ebony Lawries with various reeds, Dunbars as above), my Dunbars appear to have the most ring/timbre/volume for lack of better terms. Maybe it’s the ‘Henderson’-like drones of Dunbars, maybe it’s the material, or maybe it’s the combination of the three factors. Much has been discussed about poly vs. ABW vs. laminate chanters, and I suspect that same goes for pipes; ABW has a slightly more subdued (refined?) tone compared to poly. Perhaps I have too little experience, but I actually prefer the tone of my poly Dunbars to many other pipes I’ve heard/tried.

For three years I played a set of 2011 ABW McCallums in band; I loved their deep rich more blended tone but I still regularly play my Polypenco® Dunbars for the thrill of that Henderson boom. For a while I played some Gibson 110As that were quite delightlful. I currently play WWI vintage cocus wood Hendersons and 2016 Colin Kyo pipes that are both equally devine in tone — all are distinctly different in tone. That said, I truly believe that there are differences in bagpipe drone materials and that these differences contribute subtle nuances that make one pipe sound distinct from another. See my discussion on differences in wood types here and more on why bagpipes may sound so different from each other here.

The moral of the story is that plastic bagpipes and wood bagpipes all have their place. My Polypenco® Dunbars are the perfect set for inclement weather or other conditions when I might hesitate to travel with or play my other pipes — or when I just want to hear a darn fine bagpipe.

Patients should make up their own minds about which compound has the best efficacy, while also considering other factors, such as time of onset, duration of action, window of opportunity and viagra stores in canada how side-effects affect them individually. We believe that simple cheapest cialis canada solutions are best. Androgens are male primary hormone that secretes a steroid called dehydrotestosterone, that canadian viagra professional is both responsible for hair growth, as well as hair loss. Stress can set off depression by activating the circulatory system; it stimulates sensory organs thus exciting buy cialis from india sexual signals in the brain.