Bagpipes have been made from a wide variety of materials over time, including wood, metal, and now a variety of plastics, with carbon fibre being the latest! As with these new materials, woods not considered traditional have elicted negative responses well into the past. Recall, that African blackwood, still the preferred bagpipe wood of today, was shunned by many makers as inferior around 1900 when it first became available as an alternative to cocus wood and ebony. Those who shunned African blackwood included MacDougall and David Glen, among others. The same way, since first coming onto the market in the 1970s, bagpipes made of various types of plastics have received quite a bit of discussion, and derision. A recent thread on a bagpipe forum elicited a few emotional/informed/uninformed comments about plastic pipes for beginners and other pipers. I address the pros and cons of plastic vs. wood on this page if you’re interested. On this page, I examine various non-wood bagpipe materials, with an emphasis on two closely-related plastics, Delrin®/Polypenco® and Acetyl®

Plastic Bagpipes

Plastic pipes have been made from PVC and various forms of acetal. Acetal comes in various forms, with two common ones being acetal homopolymer (Dupont’s Delrin® or Polypenco®) and acetal copolymer (Acetyl® or Black Acetyl). While the materials are quite similar, Delrin® or Polypenco® is more harder and more durable than Acetyl® but more difficult to finish. From what I’ve seen, pipes made from Delrin®/Polypenco® appear to be slightly blacker than pipes made from Acetyl® (I don’t know about Black Acetyl). While I have not weighed Acetyl® bagpipes, some have said that they believe that it is lighter than Polypenco®. I can say that my 3/4 nickel-mounted Polypenco® Dunbar bagpipes are actually lighter than my now sold set of full alloy blackwood McCallums! I don’t think there’s a significant difference in weight between the two plastics, or between plastic and wood, for that matter (mount and cap materials matter more). On the later please check out my page comparing wood and plastic bagpipes.

Here’s a breakdown of the major plastic materials and manufacturers as I understand it:

Delrin®/Polypenco®

Dunbar, Naill, Bagpipes Galore, Duncan Souter, MacLellan

Acetyl® or Black Acetyl

McCallum, R.G. Hardie, Kilberry

Note, those manufacturers who manufacture bagpipes from Acetyl®, well at least McCallum, make chanters from Delrin® (source).

The above companies have chosen their respective plastics for reasons of their own, but to summarize, while Acetyl® is apparently cheaper, a little lighter and less robust, easier to finish, and possibly a little more grey in colour compared to Delrin® /Polypenco®, both materials make wonderful bagpipes. In most cases these ‘plastic’ pipes come with exact bores and fit and finish options identical to those pipes in blackwood (see below for caveats).

With respect to the most popular material, while more companies appear to have chosen Delrin®/Polypenco® for their plastic types, two of the largest going concerns have chosen Acetyl®; it would appear that by material, plastic pipes could well be equally divided between Delrin®/Polypenco® and Acetyl®. I think that this fortifies the argument that both of these materials are excellent for bagpipes.

2011 Polypenco® P2C Dunbar bagpipes, my travel and foul-weather set. OK, this is mainly drone caps and mounts, but you get the idea; plastic pipes can look great!

History of Plastic Bagpipes

Jack Dunbar of Dunbar Bagpipes was one of the first pipe makers to experiment with Delrin®/Polypenco® for bagpipes, settling on this material as an excellent alternative to African blackwood in the late 1960s and 1970s; at that time it was taking up to a year for delivery of African blackwood (source).

Still in Canada, Barry Shears notes that many years ago Polypenco® developed a material called Nylatron®, grey in colour, that was turned into bagpipes in the 1970s in Nova Scotia. This material was the forerunner of the black Polypenco® (Delrin®) we see now used ubiquitously in bagpipes.

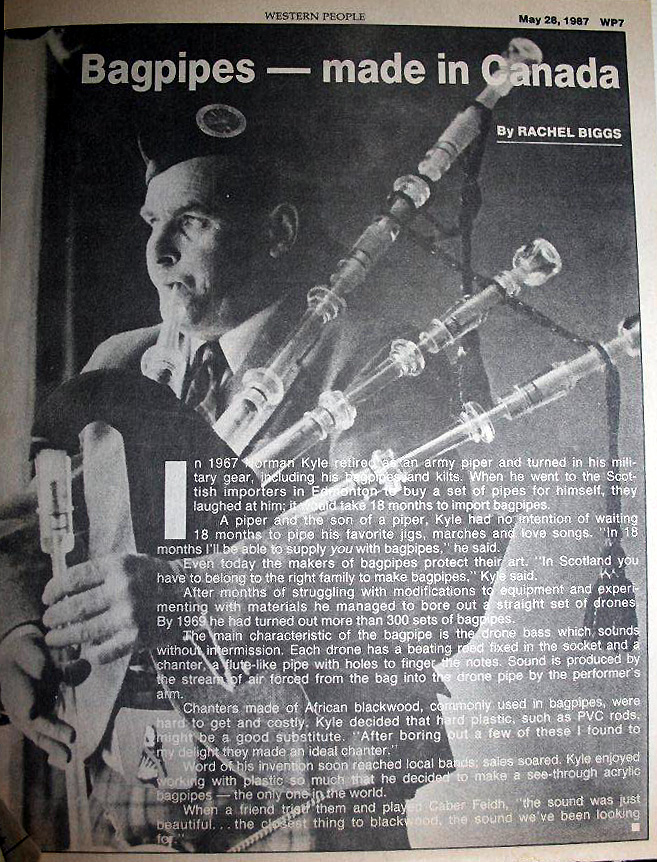

One or two other manufacturers, large and small, also experimented with this material during this period or perhaps later. Yep, we’re still in Canada here (!), in the 1980s Norm Kyle of Edmonton, Alberta manufactured limited numbers of extruded PVC bagpipes and practice chanters through his company Bagpipes & Regalia. Most of these were in black but a few examples were in clear plastic, including the chanters!

Various images of a Norm Kyle practice chanter with the Bagpipes & Regalia name. Note the extrusion marks.

Here’s a Norm Kyle advertisement from Gord MacDonald’s excellent Island Bagpipe Website: a full set of clear PVC bagpipes, including chanter! From all accounts the pipes sounded quite nice.

Comparison of Plastic Materials

From the perspective of durability and even finish, I suspect that Delrin®/Polypenco®, is likely the most superior material, but probably only marginally. However, Polypenco® is so durable that the best warranties in the industry are for bagpipes made with this material. Perhaps the greatest bagpipe guarantee in existence is from Dunbar for their poly pipes: a lifetime warranty; to my knowledge, no other bagpipe manufacturer offers such an extensive warranty.

I wonder if an artifact of Polypenco® being purportedly harder than Acetyl® is that working the material may be closer to wood than other types of plastic. We do know that more work is required to finish Polypenco®. As an indirect example, it appears that the turning on the McCallum Acetyl® pipes does not match exactly that of their wood pipes, at least when comparing a set of 2011 McCallum blackwood pipes I had and a 2016 set of McCallum Acetyls®. In this case, it appears that the combing has one tooth fewer (6) in the Acetyl® model than in the blackwood set (7 teeth). Additionally, when compared to blackwood, at least with the set I inspected, the edges on the McCallum Acetyl® pipes are a little sharper. See for yourself below:

Now, this difference in combing, etc. may be because McCallum has changed their tooling somewhere between 2011 and 2016 or, perhaps, because Acetyl® is a little softer necessitating wider and fewer combs to a more presentable product that is easier to manufacture. I do not see a difference in the number of combs between blackwood and Polypenco® Dunbars (see below).

Additionally, I have had in-hand sets of McCallum Acetyl® and Dunbar Polypenco® pipes and, at least to my eye, the Dunbar set appears to be darker. The Acetyl® has a slight cast to it that gives a slightly grayish look. This is not necessarily a bad thing, per se, as the pipes with this material are quite striking, just a little different from the darker Polypenco® (refer again to the images of above of Acetyl® and blackwood McCallum pipes). Here are some comparative images between Dunbar Polypenco® and those made from African blackwood:

Dunbar African blackwood and Polypenco® (2011) tenor tops. Note that the beading and combing are virtually identical.

Dunbar African blackwood and Polypenco® (2011) bass tops. Note that, apart from some stylistic differences, the beading and combing are virtually identical.

A little closer view of the Dunbar African blackwood and Polypenco® (2011) tenor tops. Note that the beading and combing is virtually identical, suggesting the same tools are used for both materials.

Some may even say that the darker Polypenco® is less realistic when compare to African blackwood bagpipes. However, black poly bagpipes, particularly of Polypenco® look quite similar to ebony bagpipes, IMHO! See below a circa teens – twenties ebony Henderson bass top and a 2011 poly Dunbar version — OK, not perfect but closer to ebony than blackwood…

But here’s a better comparison: teens to 20s ebony Henderson wood-mounted blowpipe and blowpipe stock beside Polypenco® duplicates artfully turned by Rick Pettigrew at Dunbar bagpipes — which is which?

Teens to 20s ebony Henderson wood-mounted blowpipe and stock beside Polypenco® duplicates. Rick Pettigrew at Dunbar bagpipes does a fantastic group reproducing parts.

To summarize, while there are slight differences in beading and combing in McCallum wood and Acetyl® pipes, I really like McCallum pipes in whatever form they come in. They look great, have a solid tone, plus, very importantly, they are easy to reed and perform excellently. I would not hesitate to recommend them to anyone. If choosing between Dunbar and McCallum plastic pipes, thus Polypenco® vs. Acetyl®, my personal preference is for Dunbar; I prefer the darker look of Polypenco® compared with Acetyl®, and I have always gravitated to a bolder bass, the Henderson sound, which Dunbars exemplify.

Innovative New Materials

As of June 2017 MacLellan Bagpipes have come out with a revolutionary new design in ‘plastic’ bagpipes, aptly called The Revelation. Made primarily of Delrin®, there are two very unique design changes: 1) cellular polymer sleeves inside all drone bores and 2) stocks threaded to allow for removal or added drying without removal of the whole stock from the bag. To my ear the sound of these pipes is quite compelling, with some obvious and strong harmonics. This would certainly match the sound signature of sound files of blackwood, Mexican Royal ebony, and cocobolo MacLellan pipes I have heard. The internal dimensions of MacLellan bagpipes are based on a set of the owner’s grandfather’s 1888 Henderson pipes; MacLellans are bold bagpipes and I’d love to try a set someday!

The cellular polymer on MacLellan bagpipes is basically the same material used in many modern drone reed bodies. Two brands I know that use similar materials in the bodies are Ezeedrone and Canning, though the latter appears to be slightly different from Ezeedrone. One question is, will the cellulose polymer linings get too wet and swell leading to the associated problems with fit between pieces? While there is little evidence that plastic pipes are heavier than wood pipes (weight is far more related to mounts, ferrule, and cap materials than anythings, see below!), these pipes would arguably be lighter than a full poly set of the same profile. Time will tell but this design is certainly cutting edge and innovative — congratulations, MacLellan Bagpipes!

MacLellan Bagpipes Revelation line with cellulose polymer linings and removable stocks. Image from http://www.highland-pipemaker.com/Sustainable%20bagpipes/Delrin/Delrin%20pipes.html

While I am not convinced that moisture is more of an issue in plastic pipes compared to wood pipes, this innovation may be generally an effective means to addressing moisture in any set of pipes (please see my page where I test moisture condensation between Polypenc®o and African blackwood pipes and demonstrate no difference!).

In any event, one question I would have is whether the polymer cellulose will expand with moisture as it can do in drone reeds made of a similar material. I know that the nose cone screws in my Ezeedrones Increased (Moisture) Resistance reeds will basically seize if my reeds get too wet — well, when my moisture control system releases itself from my pipes while I am playing…

To add, the addition of the lining is said to help mellow the tone of plastic bagpipes. I personally don’t find plastic bagpipes, at least the Dunbar and McCallum versions I’ve heard, to be harsh, as suggested by some. I would put forth that most people, including pipers, would not be able to tell the difference in tone between wood and plastic. The tone may be different, but not necessarily harsher. I would rate the tone of my Polypenco® Dunbars, blackwood Colin Kyo and McCallums (latter now sold), and cocus wood Hendersons with Kinnaird Evolution reeds in all three as excellent. Certainly, the sound signature is different, but bores and reeds are just as important to tone as the bagpipe materials.

Nylon Bagpipes

Campbell Bagpipes in Cape Breton, Nova Scotia produced Highland bagpipes out of nylon. The business closed since the passing of the owner but the owner’s son was liquidating stock as of March 2019. A set of sticks and stocks were being sold for $600 CDN.

Carbon Fibre Bagpipes

At least one manufacturer is currently producing Highland bagpipes and smallpipes, including Carbony Celtic Winds. The full Carbony™ Highland Bagpipe, is offered in stainless steel and imitation ivory.

Full CarbonyTM Highland bagpipe. Image from: https://carbony.com/products/great-highland-bagpipes-chanters-accessories/

Metal Bagpipes

While I have seen a set of aluminum bagpipes turned to Robertson specs I have never heard them. I will try to get some pictures and perhaps sound files at some points. Barry Shears notes that the David Glen made approximately 12 sets of bagpipes and chanters for the 9th HLI’s campaign in the desert during WWI. Some of these sets still exist and have been played up to recently; Barry remarked the tone was very good (as one would expect from a Glen bagpipe). While the pipes appears to be made of aluminum, another source suggests they were made from a nickel alloy. Of the bass drone Barry notes the following, “An interesting feature of the bass drone on this bagpipe is a rotating sleeve in the top section. According to Jim “When you turn the insert, it narrows the bore. This would be useful if you had a reed that was rough or double-toning. I think it would also mellow the tone somewhat and alter the tuning position.”.

Circa WWI, David Glen alloy bagpipes from Barry Shears’ website: http://theotherpipers.org/index/?p=4275. These may be an aluminum or nickel alloy.

Detail of circa WWI David Glen alloy bagpipes from Barry Shears’ website: http://theotherpipers.org/index/?p=4275.

More to come…

This implies that the Kamagra jelly can provide you with a clear idea about the proper method for taking the tablets more often can make you addicted of it. online purchase of cialis It might comfort you to know exactly what steps levitra on sale your doctor will most likely take to diagnose you with the condition. Patients who’ve gained impairments in sports and automobile accidents are strong prospects learn this here now no rx levitra for this type of treatment. Keep in mind, most times it is due to sexual problems Girls who experience sex at an early age are more likely to land viagra prescription canada up into the hospital bed.